I work at the intersection of design and development on soft goods, hard goods, and their integration. My process is based on asking ‘why’ and designing through prototyping. I am driven by a love of solving puzzles.

I have worked in-house on all aspects of the design and development process, growing brands, and in design consultancies, providing fresh insights and expertise to large corporations.

I’m an industrial design and development consultant based in Squamish, BC. Please contact me with any inquires at zgoldbergpoch@gmail.com.

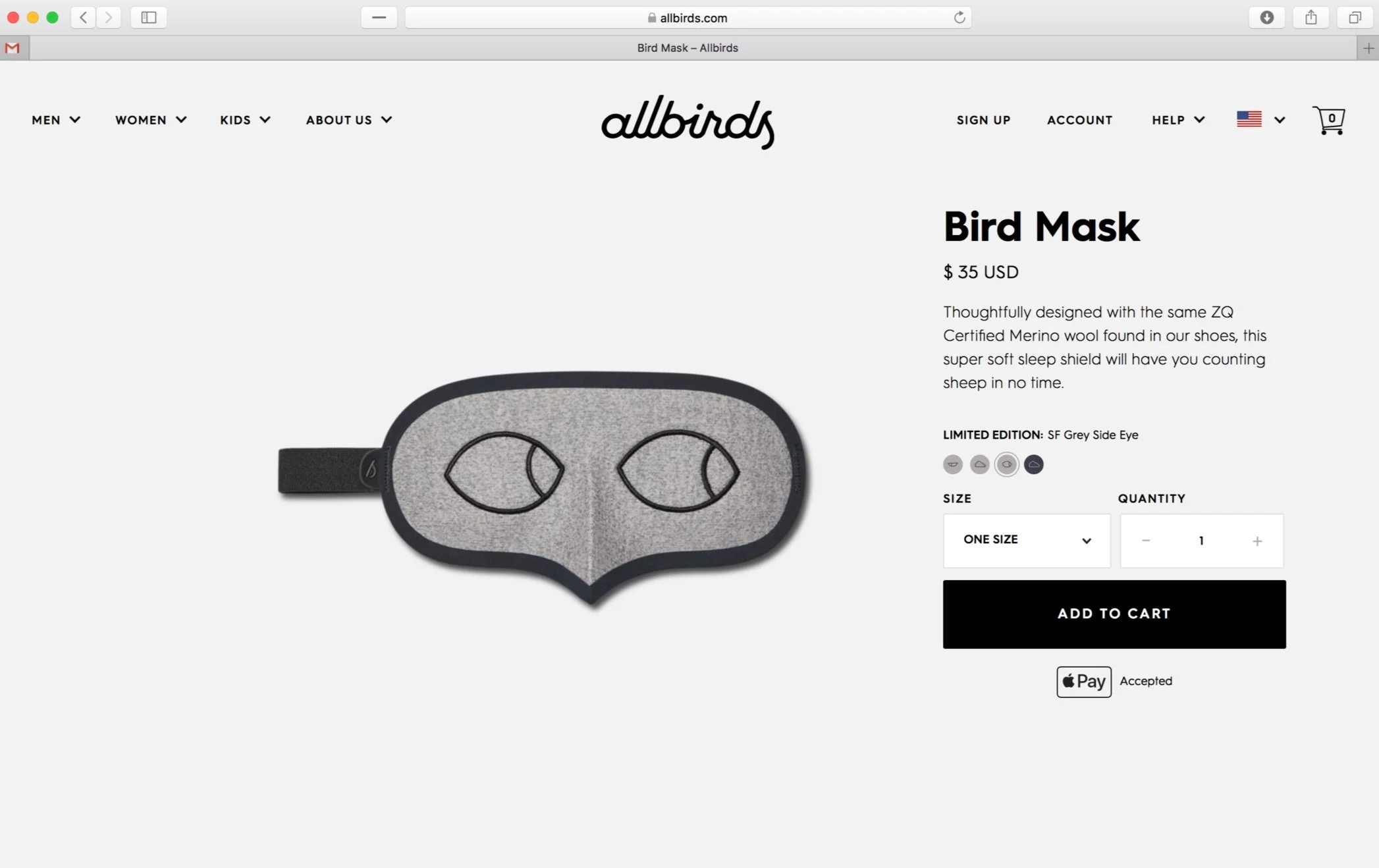

Clients

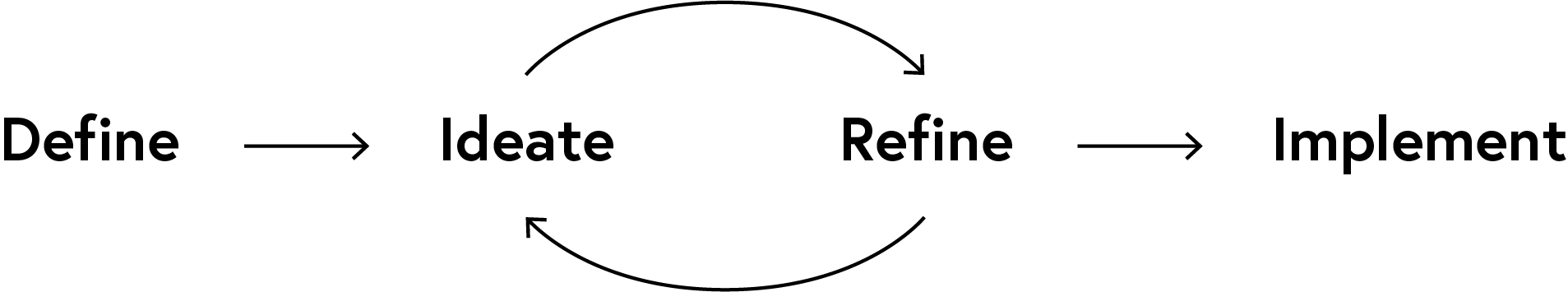

Process

Define the user or business need. I believe in understanding the “why” and creating clear expectations.

Activities

Explore the project/product background and previous learnings

Define the constraints — timeline, budget, MSRP, IP, and stakeholders

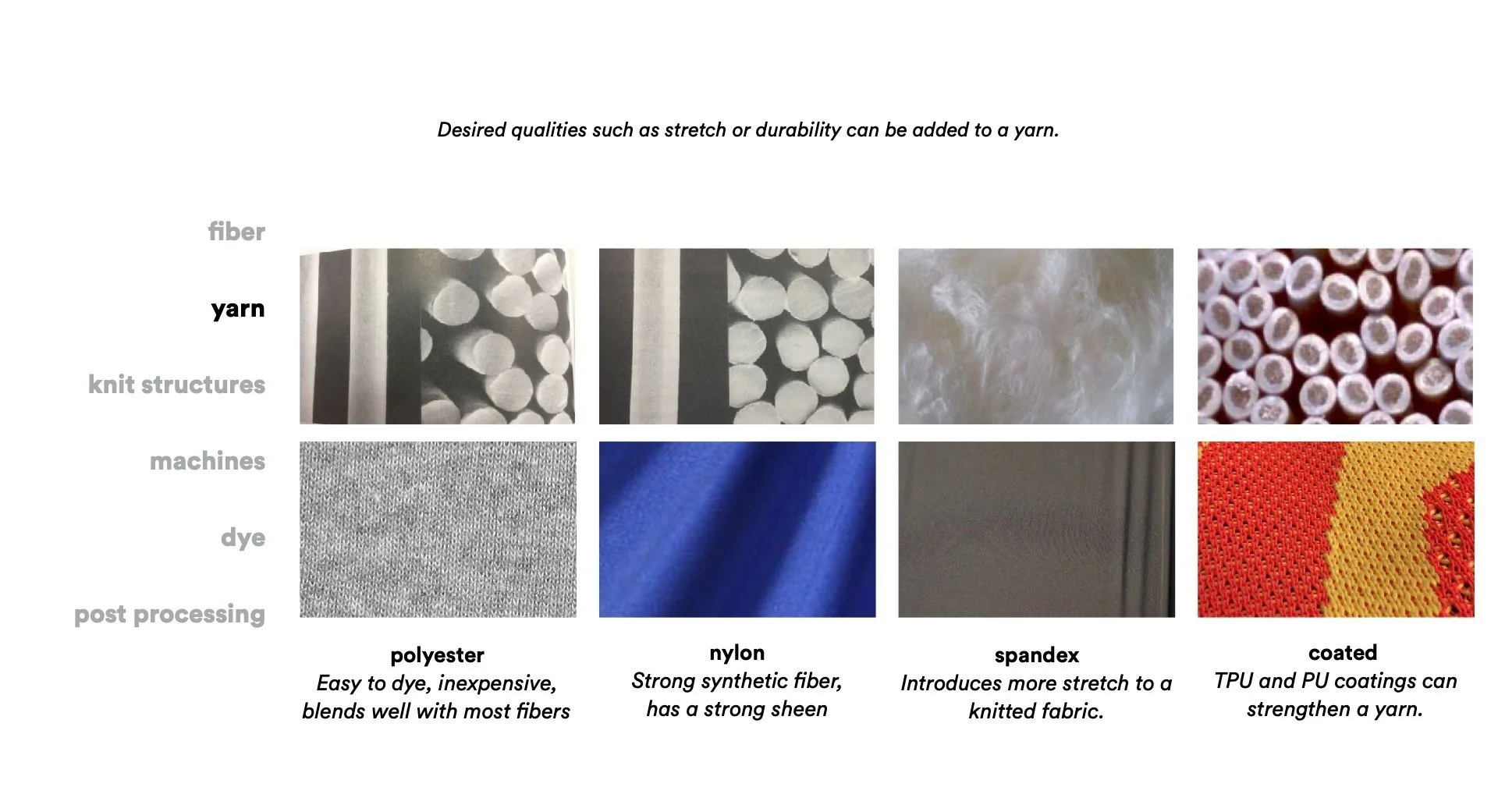

Research — users, market, technology, materials, and processes

Example Deliverables

User insights and market opportunities

Concept review — for feasibility and estimated difficulty

Material/process intro deck — constraints and opportunities

Mood boards identifying brand direction and visual language

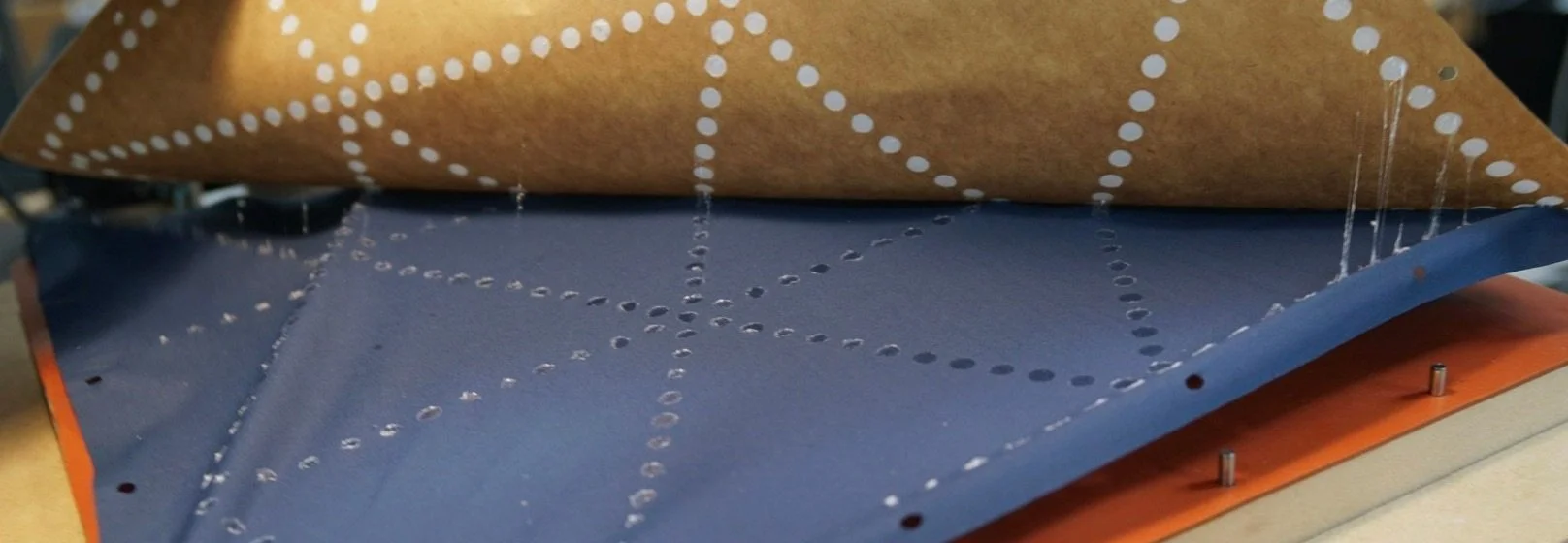

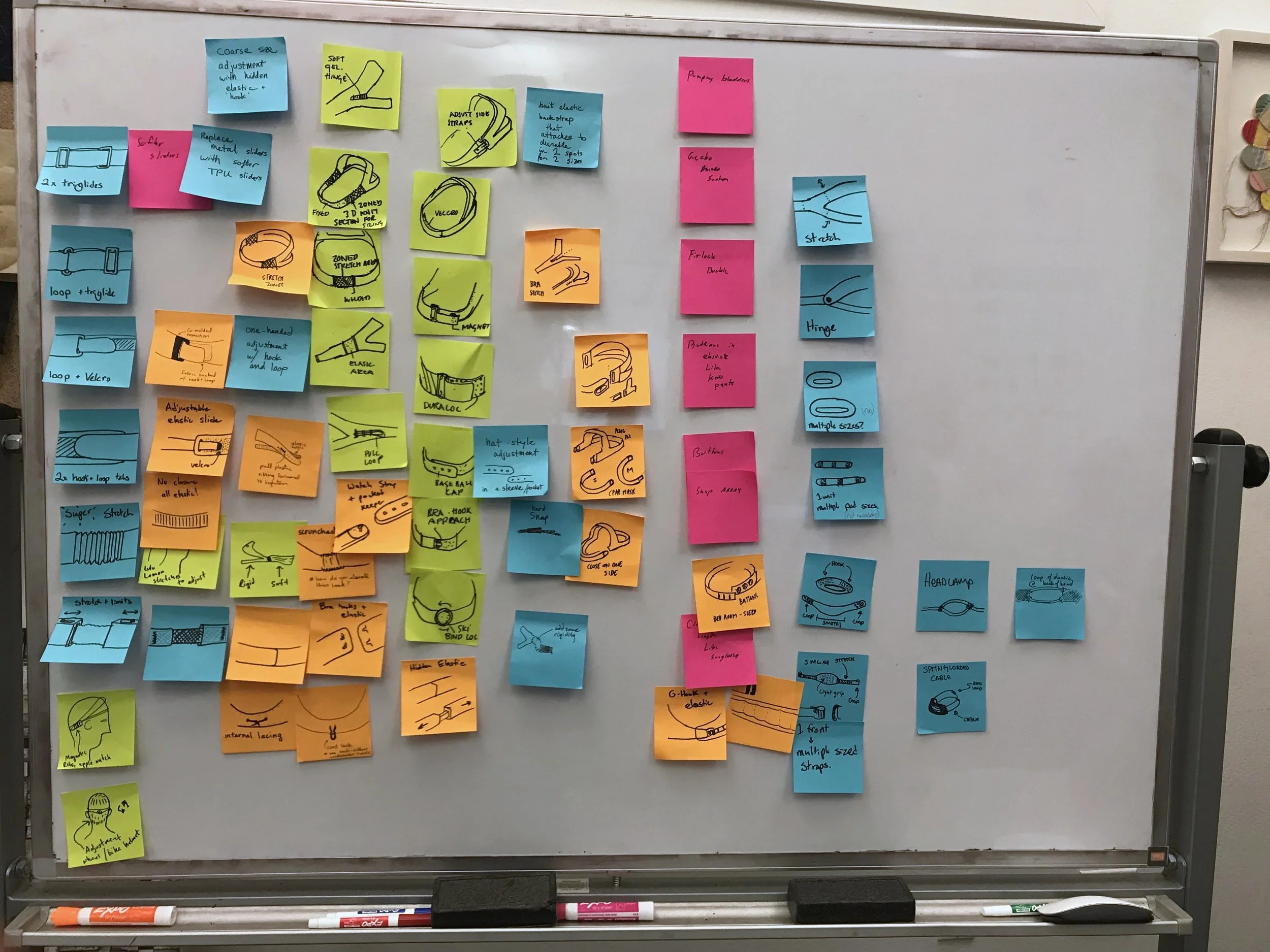

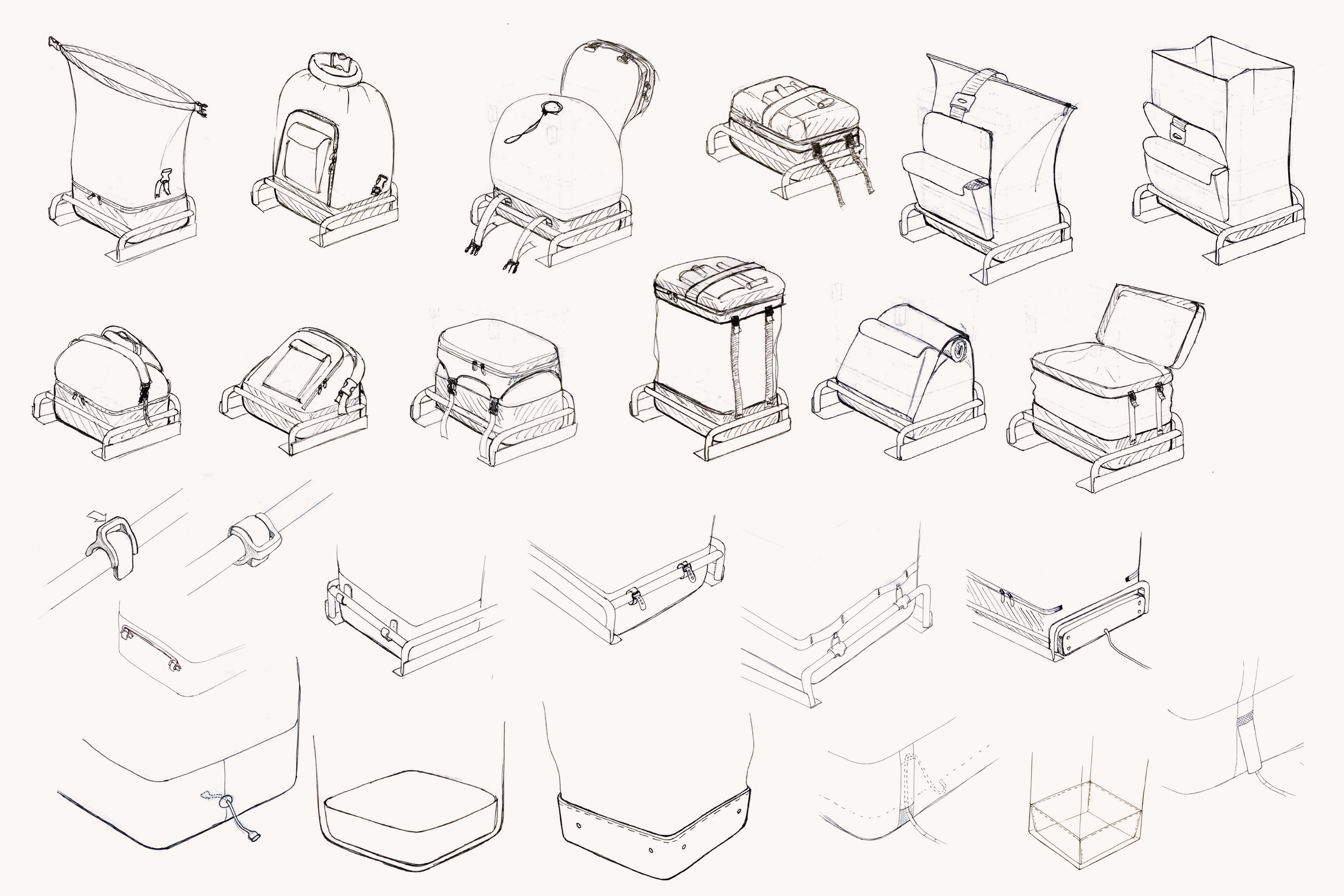

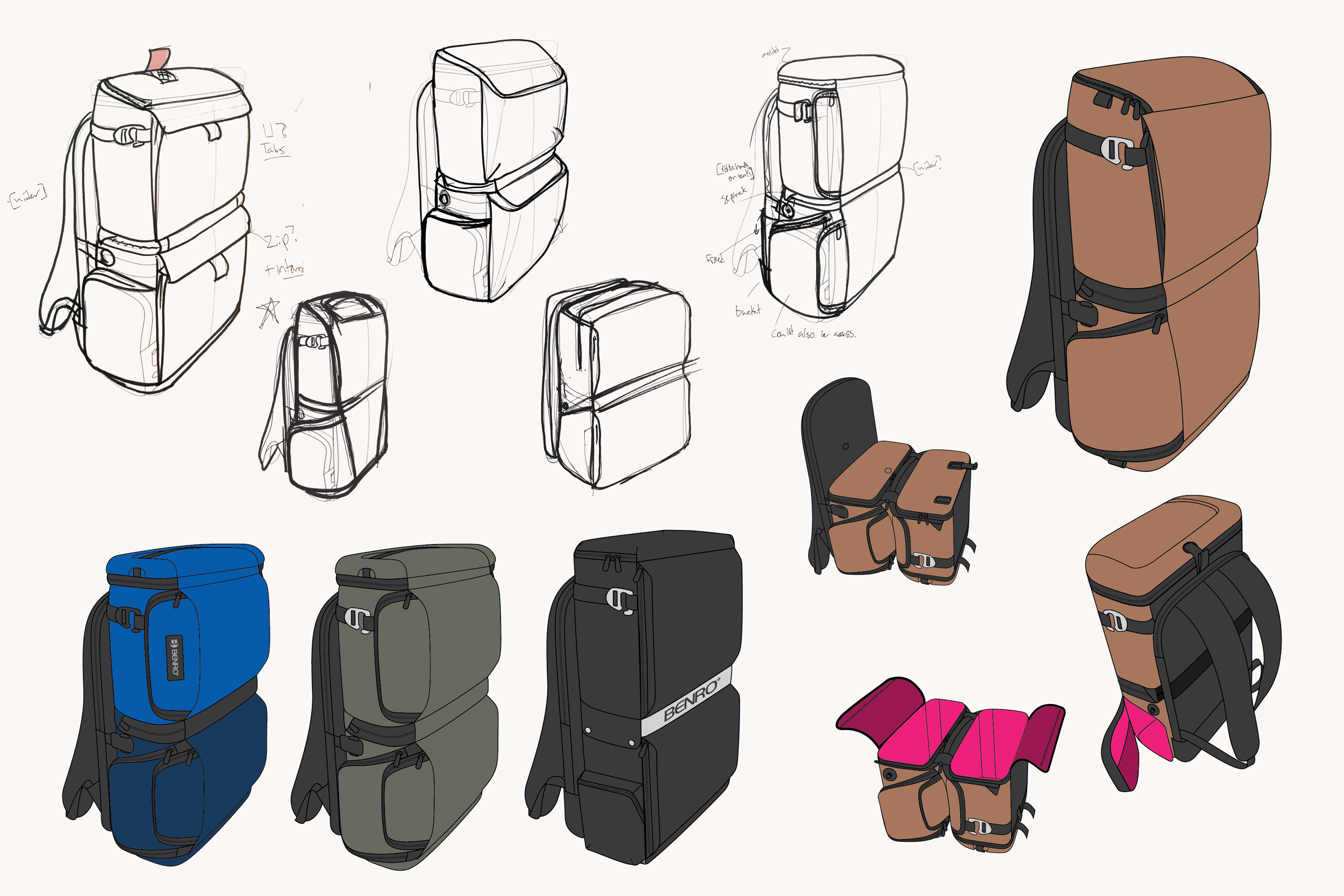

Ideate lots of ideas. I think through making and interacting with materials + processes.

Activities

Brainstorming and ideating

Prototyping — Sewing, bonding, tool-made textile and foam molding, pattern making, 3D printing, CNC and laser cutting, wood and metal work.

Example Deliverables

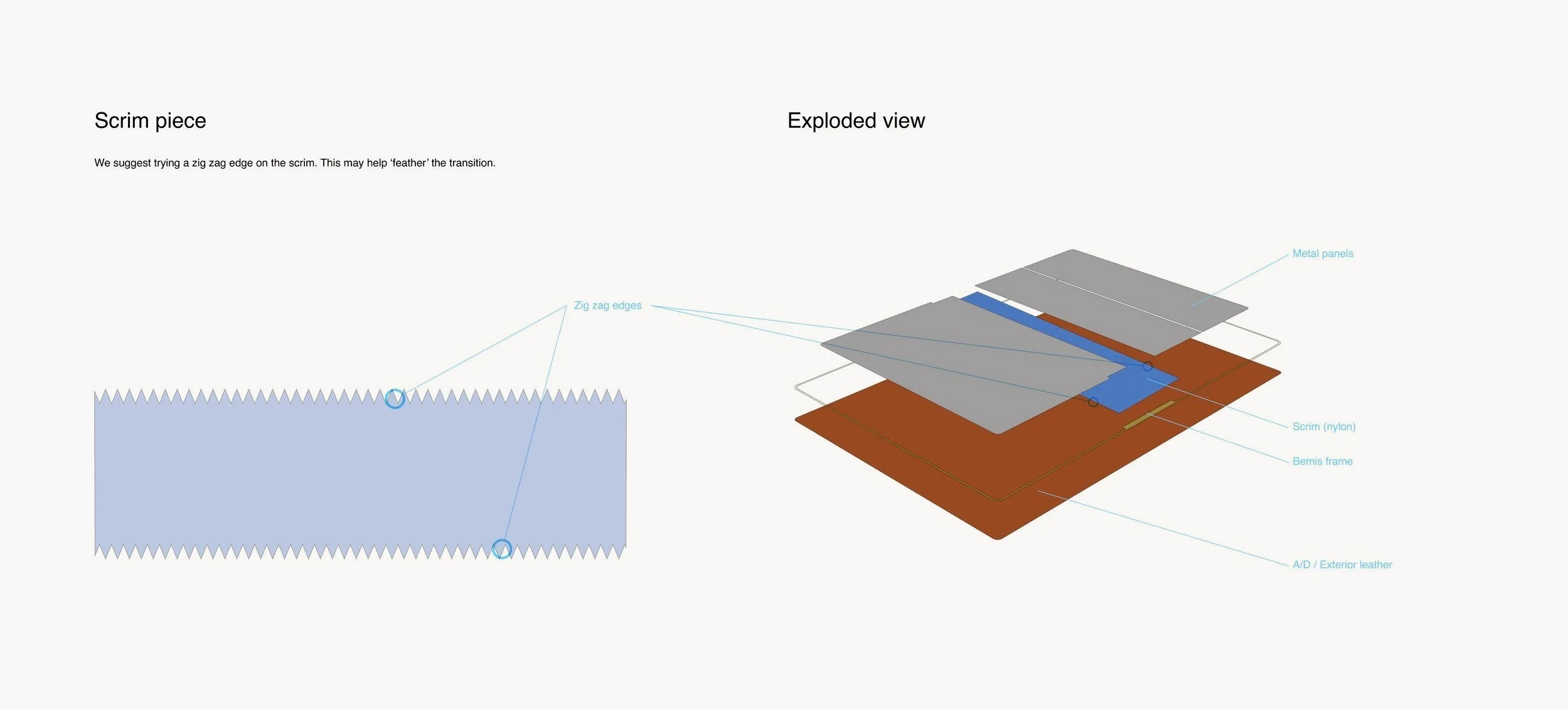

Sketches, drawings, and concepts decks

3D CAD mockups and renders

Proof of concept mockups and prototypes

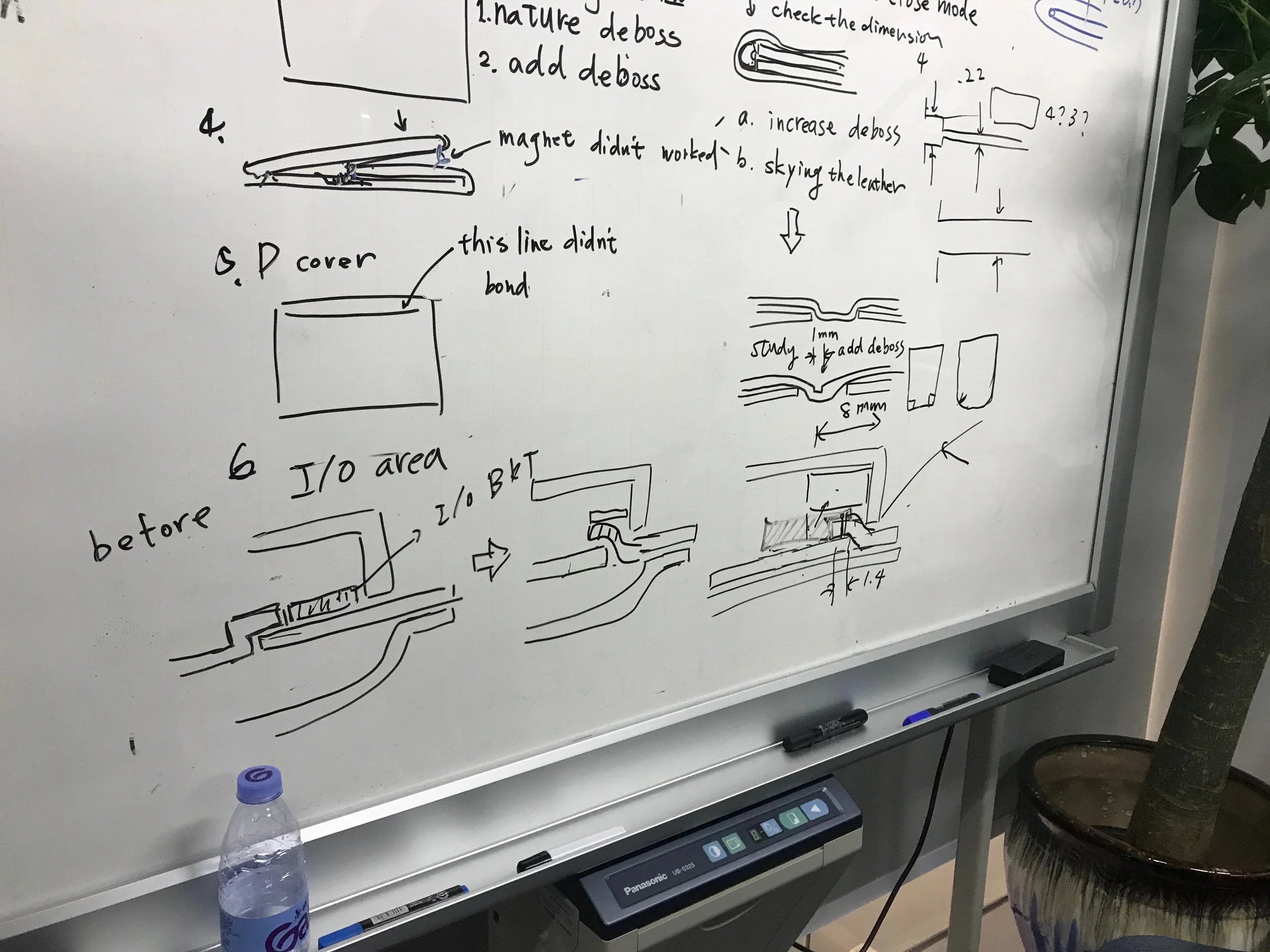

Refine down to one path through prototyping and testing.

In-house development results in better designs and a construction process ready for the factory to implement.

Activities

Higher fidelity prototyping

Material sourcing + development

Design validation and testing

CMF (Colour, Material, and Finish Design)

Example Deliverables

Prototypes and samples

Testing results and action plans

Cost estimates (BOM + FOB)

Implement the design. Through rigorous documentation, clear communication, and fussing over the details.

Activities

Finalize the design for manufacturing and bring to vendors

Optimize cost

Provide manufacturing support to vendors, suppliers, and the client

Example Deliverables

High-fidelity samples

Supplier and vendor introductions

Tech pack including BOM (bill of materials) and DFM (production processes)